Furnaces

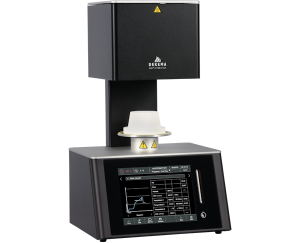

We represent high quality lines of precision sintering furnaces for Zirconium and Dental Ceramics from Dekema.

These high-performance furnaces feature innovative technology and a unique control system that provides an output of up to 200 units per batch and are available in different sizes and capacities to address the various needs of dental labs, milling centers and practices.

Key to the benefits of these low operating costs furnaces are the versatility and reliability of the heating elements that provide even heat distribution over the entire oven.

Dental Sintering Furnaces

Dental sintering furnaces are used to process dental zirconia after it has been milled into a crown, bridge, framework, or other restoration. These furnaces can reach the extremely high temperatures required to sinter zirconia to its final hardness. The sintering process, which can involve pressure as well as heat, reduces porosity and increases the density of ceramic materials such as zirconia. During the sintering process zirconia undergoes a significant amount of shrinkage. When choosing a sintering furnace for your practice or lab it is important to consider its capacity, its pre-programmed cycles and automation features. With new options for both lab and chairside sintering, producing your own zirconia restorations is faster and easier than ever.

Dental Ceramic Furnaces

Used during the production of ceramic dental restorations such as crowns, bridges, inlays and onlays, dental ceramic ovens employ high temperatures and pressures to process ceramic materials into a hardened, final state. Also called furnaces, these systems are used with both CAD/CAM milled restorations as well as with glaze systems that add a final esthetic polish. Dental furnaces are designed to work with a range of ceramic materials, and some furnaces are designed to also produce the pressure needed to press glass ceramics, and other pressable materials. Many modern dental ovens feature touchscreen controls, pre-set programs and even the ability to connect to the internet. When purchasing a furnace for your dental practice or lab it is important to make sure it can process the materials you plan to work with.

AUSTROMAT 624i

Austromat 624i Ceramic Furnace: Fire, Glaze, Crystallize or Infiltrate up to 1200°C Includes: Firing Table; Silver Wire Calibration Kit; Tweezers; USB & Ethernet Interface; Aluminum Housing; 10.4'' Color Touch Screen Display; Quartz Glass Heating Element; Vacuum Pump; Integrated Ventilation Unit; DEKEMA Internet Database Connection & Program Streaming; (1) Year Limited Manufacturer Warranty.

AUSTROMAT 674i

SINTERING ZIRCONIA

Austromat 674i

High Temperature Sintering Furnace for Temperatures up to 1560°C Includes: Firing Table for (2) Level Sintering up to Ø100mm; PTCR Kit; Silver Wire Calibration Kit; Tweezers; USB & Ethernet Interface; Aluminum Housing; 10.4'' Color Touch Screen Display; Quartz Glass Heating Element; Vacuum Pump; Integrated Ventilation Unit; DEKEMA Internet Database Connection & Program Streaming; 200g Box of Micro-Pearls Sintering Beads; Ø100mm Insulating Body Firing Table Ring; Gripper Pliers. (1) Year Manufacturer Warranty. Available Options: Temperature Upgrade to 1600°C.